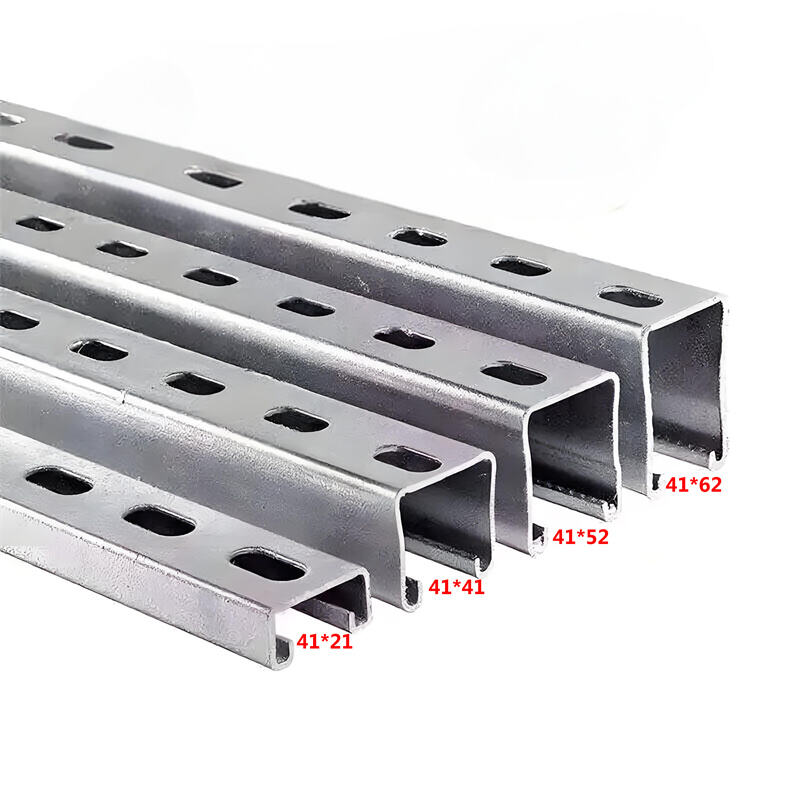

High-Strength Galvanized C-Steel Brackets PV Mounting Components with Custom Sizes Bulk Supply

Price: |

1$ |

Packaging Details: |

Wooden pallet |

Multiple specifications and sizes, zinc-aluminum-magnesium alloy coating, suitable for harsh weather, snow load 1.5KN/m2

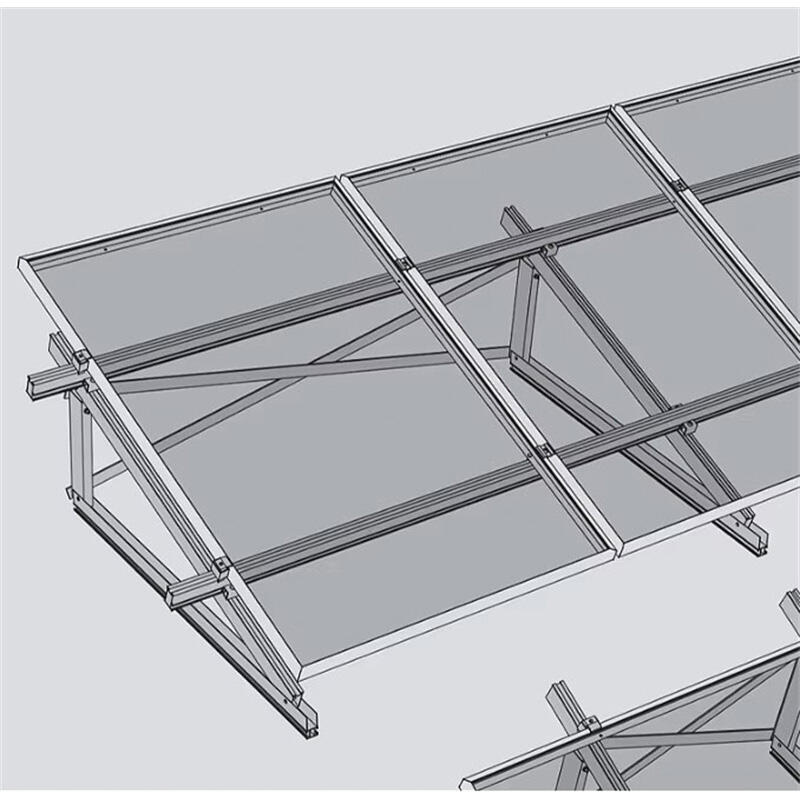

Material type of solar photovoltaic steel bracket: S350 zinc-aluminum-magnesium alloy steel; High strength: Yield strength ≥350MPa, tensile strength ≥490MPa, suitable for the high-load requirements of large-scale photovoltaic arrays. Corrosion resistance: The zinc-aluminum-magnesium coating (Zn-Al-Mg alloy layer) is more resistant to salt spray, acid rain and ultraviolet rays than the traditional galvanized layer, with a service life of more than 30 years. Triangular support structure: Through the design of triangular mechanical stability, the resistance to wind and snow loads is enhanced. Through bracket connectors; through bracket connectors; Supports splicing and expansion, suitable for photovoltaic array layouts of different scales; Material standard: S350MC (EN 10250) zinc-aluminum-magnesium alloy steel, conforming to ASTM A572 or GB/T 706 standards; Length: Standard 6 meters (customizable length) Thickness standard: 2mm (customizable thickness); Applied to large-scale ground-mounted power stations: Suitable for open areas such as deserts and mountains, supporting 6-meter-long photovoltaic module arrays. Industrial and commercial rooftops: Compatible with factory rooftops or warehouse ceilings, saving space and having strong load-bearing capacity. Complex terrain installation: such as coastal areas and areas with high salt spray, the zinc-aluminum-magnesium material has better corrosion resistance than ordinary galvanized steel. Lightweight design: Compared with traditional steel structures, S350 material reduces self-weight while ensuring strength, lowering transportation and installation costs. Environmental adaptability: Stable operation within the temperature range of -40℃ to +80℃, suitable for extreme climates. Quick installation: Standardized interface design, in combination with bolts or connectors, shortens the construction period. Foundation requirements: Concrete foundation or steel anchor bolts should be pre-embedded to ensure a stable connection between the support and the ground. Angle calibration: Adjust the inclination Angle according to the local latitude (for example, in areas with 30° N latitude, the recommended inclination Angle is 30°-35°). Anti-corrosion maintenance: Regularly inspect the connection parts and apply anti-rust paint if necessary to prevent water accumulation and corrosion. The S350 zinc-aluminum-magnesium photovoltaic steel bracket features high strength and super corrosion resistance as its core, combined with a 6-meter-long modular design and triangular structure, meeting the stability and durability requirements of large-scale photovoltaic systems. Its diverse specifications are suitable for different scenarios and are the preferred solution for ground-mounted power stations, industrial and commercial rooftops, and harsh environments.

Rooftop ground solar photovoltaic installation structure

| Place of Origin | Hebei,China |

| Brand Name | Tuoerlu |

| Model Number | Roof Ground Mounting Brackets |

| Wind Load | 60m/s |

| Snow Load | 1.4KN/m2 |

| Surface Treatment | Alloy coating |

| Product name | Solar Mounting System |

| Surface Treatment | Zinc aluminum magnesium |

| Installation Site | Flat Rooftop |

| Mounting Type | Roof Ground Mounting Brackets |

| Service Life | 25 years |

| Material | S350 |

| Packing | Wooden Case |